In modern industry and construction, Fire Resistant High Voltage Cables are not only essential for the transmission of power, they are also the lifeline for the continued operation of the system in the event of a fire or other emergency. Whether it is a petrochemical plant, an underpass tunnel, or a high-rise building, choosing the right high-voltage fire-resistant cable is critical to ensuring the safety of people and the integrity of property. This article will provide you with a detailed analysis of the structure, standards, classification, application scenarios and selection recommendations for high-voltage fire protection cables, to help you make informed decisions in the project.

What is a high-voltage fire cable?

High-voltage fire protection cable is a type of cable designed to maintain the integrity of electrical circuits under extreme conditions such as fire. It is designed to ensure the continued operation of critical systems such as fire pumps, emergency lighting, alarm systems, etc. in harsh environments such as high temperatures, flames, and water spray. These cables are typically constructed with copper conductors, clad with Mica Tape or Magnesium Oxide (MgO) as a fireproofing layer, and insulated and sheathed with Cross-Linked Polyethylene (XLPE) or Low-Smoke, Non-Halogen (LSZH) materials. It is designed to extend the operation of critical systems in the event of a fire, buying valuable time for evacuation and fire fighting.

Structural Components of High Voltage Fire Protection Cables

A typical high voltage fire rated cable consists of the following components:

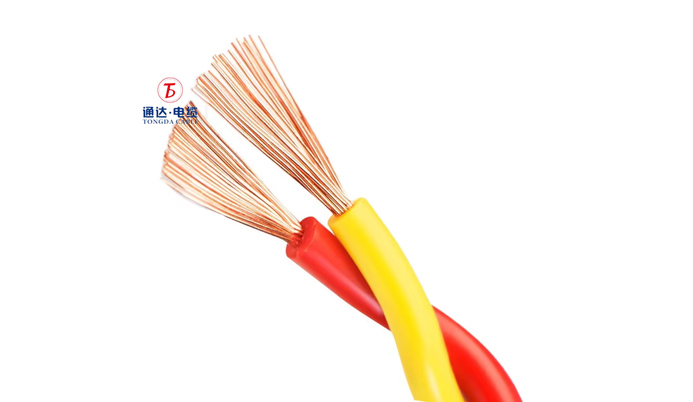

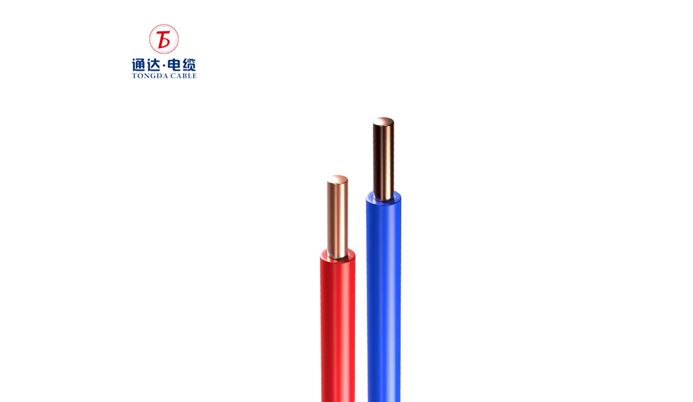

Conductor: usually made of copper, which has excellent electrical conductivity and heat resistance.

Fireproof layer: commonly used mica tape or magnesium oxide, which can still maintain structural stability at high temperatures.

Insulation layer: XLPE or silicone rubber is mostly used, with good thermal stability and electrical properties.

Sheathing: Common materials include low-smoke, non-halogen (LSZH) or flame-retardant PVC, which produces less smoke and toxic gases when burned.

In addition, some high-end products will also add a steel tape armor (DSTA) layer to enhance mechanical strength and compression resistance.

International Standards and Test Codes

High voltage fire rated cables are required to comply with a number of international standards to ensure their performance in a fire:

IEC 60331: requires cables to maintain circuit integrity at 750°C for 90 minutes.

BS 6387: Divided into classes (A, B, C, W, X, Y, Z), the cables are tested for performance under different temperatures, mechanical shocks and water spray conditions.

NEK 606: for offshore and oil platforms, requires cables to maintain circuit integrity at 1100°C.

UL 2196: US standard that tests the performance of cables in fire.

These standards ensure that high-voltage fire protection cables are able to continue to supply power in the event of a fire in real-world applications, safeguarding the normal operation of critical systems.

Main types of high-voltage fire protection cables

Based on their structure and performance, high-voltage fire protection cables can be divided into the following categories:

1. Mineral Insulated Cable (MI Cable)

Consisting of copper conductor, magnesium oxide insulation and copper sheath, it has extremely high fire resistance and mechanical strength, and is suitable for critical facilities such as hospitals and subways.

2. Low Smoke and Halogen Free Cable (LSZH Cable)

Adopting low smoke and halogen-free materials, it produces less smoke and toxic gas in fire, and is suitable for public places with heavy flow of people.

3. High temperature silicone rubber cable (Silicone Rubber Cable)

Silicone rubber material, can be stable in high temperature environment, suitable for steel, aviation, shipbuilding and other high-temperature industries.

4. Special Application Cable (Special Application Cable)

Such as P121 RFOU/TFOU cable for offshore platforms, which is characterized by high temperature resistance, low smoke and halogen free, etc., and is suitable for special environments.

Application Scenarios

High-voltage fireproof cables are widely used in the following fields:

Building and construction: high-rise buildings, shopping centers, residential areas, etc. for fire protection systems, emergency lighting, evacuation elevators, etc.

Transportation infrastructure: subways, tunnels, airports, etc., to ensure the normal operation of communication, signaling and emergency systems during fire.

Oil & Gas Industry: refineries, offshore platforms, etc. for control systems, pumps and safety equipment.

Power facilities: power plants, substations, etc., to ensure continuous power supply to critical equipment during a fire.

Medical facilities: hospitals, etc., to ensure uninterrupted operation of life support systems and communication networks during a fire.

Data centers: to protect sensitive information and keep communication systems functioning normally during a fire.

Suggestions for selection

The following factors should be considered when selecting high voltage fire protection cables:

Conductor material and cross-sectional area: copper conductor is preferred, and the cross-sectional area should meet the current carrying demand.

Fireproofing layer material: Select the appropriate fireproofing layer according to the application environment, such as mica tape or magnesium oxide.

Insulation material: XLPE and silicone rubber produce less residue when burning and have less effect on mica tape, preferred to PVC.

Sheathing materials: LSZH materials produce less smoke and toxic gases in a fire and are suitable for use in public places with heavy foot traffic.

Brands and certifications: Choose brands with clear sources and international quality certifications (e.g. ISO, BS).

FAQs

Are high voltage fire rated cables completely fireproof?

High voltage fire rated cables are not completely incombustible, but maintain circuit integrity for a certain period of time. Fire rated cables will eventually fail under an intense, sustained source of ignition. Therefore, regular maintenance and timely replacement of fire protection cables is crucial.

What is LSZH?

LSZH stands for Low Smoke Zero Halogen, a material that produces less smoke and no halogen gases when burned, which reduces the release of toxic gases in a fire and improves personnel safety.

Is it necessary to use high voltage fire cables throughout the building?

Typically, high voltage fire protection cables are used in critical areas such as fire protection systems, emergency lighting, and evacuation routes. The decision of whether or not to use them building-wide should be based on project needs and safety assessment.